MODULAR DRAINAGE SYSTEMS

A transformative solution for

civil engineering.

The modular design efficiently adapts to different

civil engineering applications, providing reliable water management solutions for infrastructure, retaining walls, land drainage, cycle paths, and more.

- Home

- >

- Civil Engineering

Advanced Material.

Manufactured from recycled tyre rubber and featuring avg. 45% void space to sustain permeability across its entire installation.

MODULAR DRAINAGE SYSTEMS

Civil Engineering Overview.

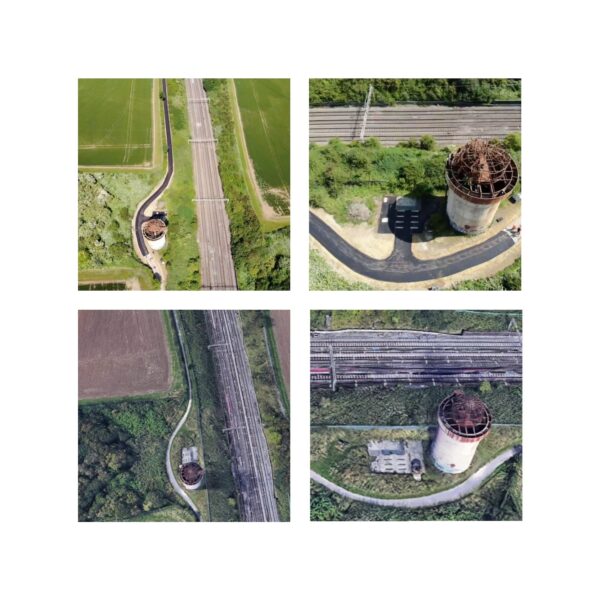

Using recycled tyre rubber formed into advanced drainage units as a replacement for perforated pipe, concrete channels and loose granular stone.

Modular drainage systems are designed to meet the unique demands of civil engineering, the transport sector and climate change resilience.

They integrate with ease into both existing drainage networks and new water management projects, providing superior control, attenuation and compliance in the drive to Net Zero and greener infrastructure goals.

Features

- Unique suite of modular drainage panels, mats, stackers and troughs

- Avg. 45% void ratio for optimal water intake

- Vertical permeability of 49 l/m²/s maximises water infiltration for drainage immediacy

- Self-correcting installation alignment

- Long-term load fatigue tested

- Chemical resistance withstands common chemicals e.g. petrol, diesel, salt and de-icer

- Temperature resistance performs consistently in both and low temperature conditions

- Manufactured from recycled tyre rubber supporting environmental sustainability

- Designed to accommodate minor ground movements, reducing risk of structural failure

- UV resistant to degradation from ultraviolet light, prolonging the lifespan of installations

- Modular design and connection options for ease of install, extension and maintenance

Advantages

Modular drainage solutions have been designed for planners, architects, drainage designers, contractors, civil engineers, environmental specialists, transport, government and local authorities to provide:

- Improved safety through enhanced design, build and water management

- Reduced excavation, spoil management and carbon footprint benefits

- Enabling adaptable whole-system approaches to drainage and water management

- Increased drainage connectivity, attenuation, soakaway and outfall options

- Improved land management and Biodiversity Net Gains

- Stronger nature-based solutions, wildlife and ecology preservation

- Infrastructure resilience against traditional drainage failure modes and climate change

- Reduced maintenance burdens

- Mitigation against formation, hardstanding and transition degradation

- Whole-life cost savings

- 60+ year design life in standard conditions for drainage parts

- 60 year design life in active loading of 50 to 95 kPa

- Unique suite of modular drainage panels, mats, stackers and troughs

- Avg. 45% void ratio for optimal water intake

- Vertical permeability of 49 l/m²/s maximises water infiltration for drainage immediacy

- Self-correcting installation alignment

- Long-term load fatigue tested

- Chemical resistance withstands common chemicals e.g. petrol, diesel, salt and de-icer

- Temperature resistance performs consistently in both and low temperature conditions

- Manufactured from recycled tyre rubber supporting environmental sustainability

- Designed to accommodate minor ground movements, reducing risk of structural failure

- UV resistant to degradation from ultraviolet light, prolonging the lifespan of installations

- Modular design and connection options for ease of install, extension and maintenance

Modular drainage solutions have been designed for planners, architects, drainage designers, contractors, civil engineers, environmental specialists, transport, government and local authorities to provide:

- Improved safety through enhanced design, build and water management

- Reduced excavation, spoil management and carbon footprint benefits

- Enabling adaptable whole-system approaches to drainage and water management

- Increased drainage connectivity, attenuation, soakaway and outfall options

- Improved land management and Biodiversity Net Gains

- Stronger nature-based solutions, wildlife and ecology preservation

- Infrastructure resilience against traditional drainage failure modes and climate change

- Reduced maintenance burdens

- Mitigation against formation, hardstanding and transition degradation

- Whole-life cost savings

- 60+ year design life in standard conditions for drainage parts

- 60 year design life in active loading of 50 to 95 kPa

Download technical documents by clicking the links below:

- Civil Engineering Overview

- Technical Specification

- Hydrotrench - Cycle Paths & Paths Quick Intro

- Hydrotrench - Cycle Paths & Paths System Overview

- Hydrotrench - Cycle Paths & Paths Introductory Leaflet

- Hydrotrench - Cycle Paths & Paths FAQs

- Hydrotrench - House Builders System Overview

- Hydrotrench - Golf Courses Overview

CMW News

News & Events.

UK Councils Prevent Flooding On Walking and Cycling Routes – Where Traditional Drainage Systems Had No Answer

-

Posted by

admin

Civil Water Management Wins DfT Sustainability Award

-

Posted by

admin

Civil Water Management Named Sustainability Finalist Ground Engineering Awards 2025

-

Posted by

admin

CWM Tackles Flooding on the National Cycle Network with DfT Rural Transport Accelerator Programme

-

Posted by

admin

Global

International Reach.

Accreditations & Awards.

Get In Touch.

To talk to our specialist drainage team call 0203 189 1468 or email in**@******************nt.com